Tilmaamaha Collar iyo Dhuumaha

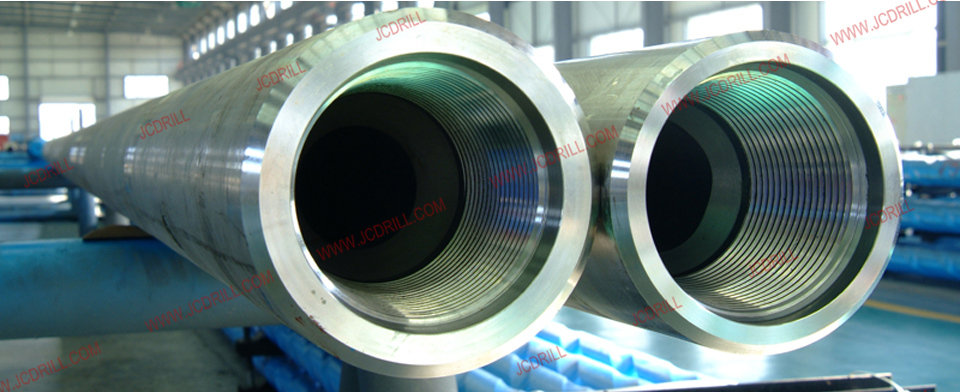

Qoorta qodista waxaa inta badan loo adeegsadaa bixinta tuubooyinka laydhka ee loo baahan yahay cadaadiska qodista, hubinta in xoog jiiditaanku u gudbiyo tuubada qodista oo ay meel dhexe uga dhigaan qaybta qodista.Marka loo eego qeexitaannada API Spec7-1, tayada maaddadu waa 4145H taas oo ah daawaynta kulaylka ka dib, daawaynta dunta adkaynta iyo fosfatada si si fiican looga hortago.Waxa kale oo lagu soo saari karaa shuruudaha macaamiisha.

Qoorta qodista miisaanka culus waa qayb muhiim ah oo ka mid ah waxqabadka Jcdrillhoos qalab qodida godka.Kuleejyada qodista waxay bixiyaan culeys yar oo qodista iyada oo loo marayo qaabab.Riig-jeexayaashu waxay awoodaan inay la socdaan miisaanka lagu dabaqay xoogaa iyagoo la socodka xisaabinta fudud, iyo miisaanka tusaha miisaanka, ee sagxadda rig.Collars-ku-xidhka ayaa caadi ahaan dhererkoodu yahay 31' cagood, gidaar qaro weyn, iyo bir culus.Waxay ku yimaadaan sanduuq by pin leh isku xirnaanta la mid ah, si ay ula midoobaan inta loo baahan yahay, si loo gaaro miisaanka la rabo.Collars-kuleelaha waxay yimaaddaan OD jilicsan, ama lagu rakibay grooves helical (collars spiral).Jink wuxuu hayaa sahay deeqsinimo leh oo ah collars birta kaarboon ee kaydka ah.Collar-kuleelaha rasaasta Ujeeddada waa in la dhex dhigo xaddi yar oo bannaan inta u dhaxaysa birta qodista, iyo meel u dhow xasiliye.Tani waa dariiq kale oo Jcdrill ku siinaya awood aad ku hagaajin karto baahiyahaaga waxqabad marka ay soo baxaan caqabadaha godka hoose.Markaad ku darto farqigan gaaban ee u dhexeeya xoogaa, iyo meel u dhow, waxaad adkeynaysaa garabka BHA xoogaa, yaraynta socodka, sidaas darteed, kor u qaadida dalool toosan.Jcdrill waxa ay kaydka ku haysaa sahay deeqsinimo leh

| m | |||||

| Naqshadeynta | O | D | ID | Dherer | Dhexroorka Chamfer |

| in | mm | + 1.6-0.0mm | + 152.4mm | +0.4mm | |

| NC23-31 | 3 1/8 | 79.4 | 31.8 | 9.15 | 76.2 |

| NC26-35 | 3 1/2 | 88.9 | 38.1 | 9.15 | 82.9 |

| NC31-41 | 4 1/8 | 104.8 | 50.8 | 9.159.45 | 100.4 |

| NC35-47 | 4 3/4 | 120.7 | 50.8 | 9.159.45 | 114.7 |

| NC38-50 | 5 | 127 | 57.2 | 9.159.45 | 121 |

| NC44-60 | 6 | 152.4 | 57.2 | 9.159.45 | 144.5 |

| NC44-60 | 6 | 152.4 | 71.4 | 9.159.45 | 144.5 |

| NC44-62 | 6 1/4 | 158.8 | 57.2 | 9.159.45 | 149.2 |

| NC44-62 | 6 1/4 | 158.5 | 71.4 | 9.159.45 | 150 |

| NC46-65 | 6 1/2 | 165.1 | 57.2 | 9.159.45 | 154.8 |

| NC46-65 | 6 1/2 | 165.1 | 71.4 | 9.159.45 | 154.8 |

| NC46-67 | 6 3/4 | 171.5 | 57.2 | 9.159.45 | 159.5 |

| NC50-70 | 7 | 177.8 | 57.2 | 9.159.45 | 164.7 |

| NC50-70 | 7 | 177.8 | 71.4 | 9.159.45 | 164.7 |

| NC50-72 | 7 1/4 | 184.2 | 71.4 | 9.159.45 | 169.5 |

| NC56-77 | 7 3/4 | 196.9 | 71.4 | 9.159.45 | 185.3 |

| NC56-80 | 8 | 203.2 | 71.4 | 9.159.45 | 190.1 |

| 6 5/8 REG | 8 1/4 | 209.6 | 71.4 | 9.159.45 | 195.7 |

| NC61-90 | 9 | 228.6 | 71.4 | 9.159.45 | 212.7 |

| 7 5/8 REG | 9 1/2 | 241.3 | 76.2 | 9.159.45 | 223.8 |

| NC70-97 | 9 3/4 | 247.7 | 76.2 | 9.159.45 | 232.6 |

| NC70-100 | 10 | 254 | 76.2 | 9.159.45 | 237.3 |

| 8 5/8REGc | 11 | 279.4 | 76.2 | 9.159.45 | 266.7 |