| Xaalad | Cusub | Xidhiidhka Tapered | 7,11,12 Degree |

| Warshadaha lagu dabaqi karo | Hawlaha dhismaha , Tamarta & Macdanta | Faa'iidada | Waxqabad Sare |

| Miisaanka (KG) | 0.3 | Dhexroorka | 30-46mm |

| Fiidiyowga kormeerka-baxaya | Bixiyay | Nooca | QODAY QODAY |

| Warbixinta Tijaabada Mashiinada | Bixiyay | Nooca Mashiinka | Qalabka qodista |

| Nooca Suuqgeynta | Alaabta caadiga ah | Qalab | Birta aan lahayn, Birta Manganese Sare, Carbide + bir tayo sare leh |

| Magaca Summada | JCDRILL | Nooca Habaynta | Been abuurasho |

| Nooca | QODAY QODAY | Codsiga | Macdanta macdanta, qodista dhagaxa |

| Nooca Mashiinka | Qalabka qodista | Alloy Steel | 42CrMo |

| Qalab | Birta aan lahayn, Birta Manganese Sare, Carbide + bir tayo sare leh | Xidhiidhka Tapered | 7,11,12 Degree |

| Nooca Habaynta | Been abuurasho | Faa'iidada | Waxqabad Sare |

| Codsiga | Macdanta macdanta, qodista dhagaxa | Dhexroorka | 30-46mm |

| Alloy Steel | 42CrMo |

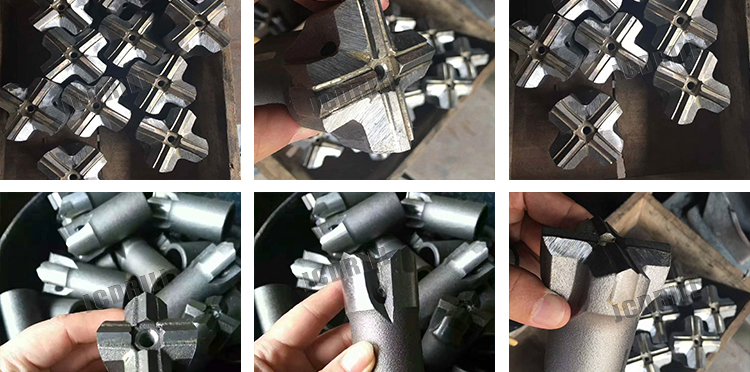

7,11,12Tapered Degree Taper Taper Cross Bit

Hordhac iskutallaab ah:

Dhagaxa iskutallaabta ah waxaa loo isticmaali karaa xaalad kasta oo qodista dhagaxa, si dhib leh uma saamayso qaabka qalabka qodista iyo waxqabadka dhagaxa.Guud ahaan, qashin-qubka waxaa inta badan loo adeegsadaa dhagaxa adag, iskutallaabta iyo xoogaa badhanka ayaa inta badan loo adeegsadaa dhagaxa fissural-ka.Waxaa inta badan loo adeegsadaa qodista haadka miinada iyo godadka qarxinta dhammaan shaqooyinka qodista ee ku habboon usha daloolista.Dhagaxa kala duwan, waxaanu dooranaa daawaha kala duwan si loo kordhiyo nolosha shaqada ee qashinka laydhka.

| Iskutallaab Qodista | |||

| Magaca Alaabta: | Tungsten carbides-ku-duuban oo la duubo | ||

| Noocyada | Dhagaxa iskutallaabta ah ee iskutallaabta, Biraha iskutallaabta tapered, badhanka tapered / 34mm badhanka laydhka | ||

| Codsiga:: | U isticmaal dhagaxa granite iyo dhagaxa marmar, macdanta dahabka, jidka tareenka, tunnelka, iwm. | ||

| Tilmaam: | Biraha daloolka duuban ayaa isku xira birta daloolka duuban ee daloollada | ||

| Qalab: | Carbiid tayo sare leh iyo bir tayo sare leh | ||

| MOQ: | 1pcs | ||

| Waxaan u qaabeyn karnaa oo soo saari karnaa iyadoo loo eegayo baahidaada dhexroorka, godad hawada nambarka iyo qaabka badhanka carbide. | |||

| Noocyada laydhka | Dhexroorka (mm) | Xagasha Taper (Degree) | Dhererka (mm) |

| Xirmooyinka birta ah ee duuban | 20/22/28/30/32/34/36/38/40 | 4 darajo/6 darajo/7 darajo/11 darajo/12 darajo | 50/55/60/71/80 |

| Xirmooyinka isdhaafka ah ee duuban | 24/26/28/30/32/33/34/35/36/3/38/40/42/48/50/55 | 50/55/60/71/80 | |

| Qaybaha badhanka la duubay | 28/29/30/32/33/34/35/36/37/38/40/41/42/45 | 50/55/60/71/80 | |

| Tirada Dalbashada Ugu Yar | N/A |

| Qiimo | |

| Faahfaahinta Baakadaha | Xidhmada Dhoofinta caadiga ah |

| Waqtiga dirida | 7 maalmood |

| Shuruudaha Lacag-bixinta | T/T |

| Awood-siinta | Iyada oo ku saleysan Amarka Faahfaahin |