| Xaalad | Cusub | Midabka | madow ama Customized |

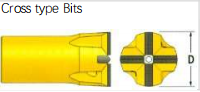

| Warshadaha lagu dabaqi karo | Hawlaha dhismaha , Tamarta & Macdanta, Tunneling | Dhexroorka | 45MM-76MM |

| Fiidiyowga kormeerka-baxaya | Bixiyay | Nooca dunta | R25,R28,R32,R38,T38,T45,T51 |

| Warbixinta Tijaabada Mashiinada | Bixiyay | Erayada muhiimka ah | Gacan-isku-xidhka |

| Magaca Summada | Jcdrill | Codsiga | Macdanta / Quarrying / Tunneling/Qarax |

| Nooca | Gacan-gacmeedka | Dhererka | 150MM-235MM |

| Nooca Mashiinka | Qalabka qodista | Sameynta | Adag / Dhexdhexaad Adag / Jilicsan Samaynta Dhagaxa |

| Qalab | Carbide | Nooca buundada | Semi-buundo / Buundo-buuxa |

| Nooca Habaynta | Been abuurasho | Walxaha ceeriin | Birta aluminium tayo sare leh |

| Isticmaal | Macdanta |

Hordhac

Sharaxaada

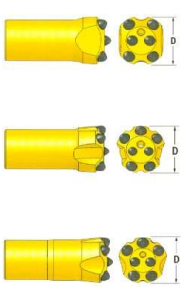

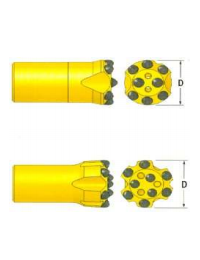

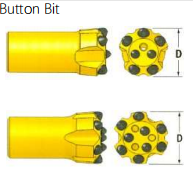

Gacmaha isku dhafka ah ayaa la heli karaa oo leh noocyada buundada nuska ah iyo kuwa buuxa labadaba, iyo sidoo kale isku xirka adabtarada.

Isku xirka buundada nus-buundo, ilaa hadda waa tan ugu caansan, waxay leedahay buundo yar oo aan xadhig lahayn oo dhexda taal.Usha daloolku ma dhaafi karto badhtamaha isku xidhka, dhexroorka yar ee ulaha ayaa isku xidha aagga buundada dhexe ee isku xidhka.Isku xirka buundooyinka nus-buundada ah ayaa aad ugu habboon mashiinnada qulqulka sare.Inta badan xadhkaha (R) iyo Trapezoidal (T) isku xidhayaasha dunta ah ayaa ah kuwo siman.

Isku xirka buundada buuxa waxay leedahay faa'iido weyn oo ah inay si togan u tirtirto suurtagalnimada isku-xidhka inay ku gurguurto kala-goysyada dunta leh.Isku-xidhyadan, ayaa sida caadiga ah loo isticmaalaa dunta Trapezoidal, codsiga qodista dusha sare, waxay leeyihiin sifooyin fiican oo aan la isku dhejin waxayna u muuqdaan inay ilaaliyaan kala-goysyada adag.Isku xirka buundada buuxa ayaa leh fursad yar oo ah isku xidhka waxayna ku habboon yihiin mashiinnada ku qalabaysan wareeg madax bannaan.

Isku xirka adabtarka ayaa la adeegsadaa marka laga beddelayo hal nooc, ama cabbir, mid kale waxaana caadi ahaan loo baahan yahay oo keliya xaalado gaar ah.

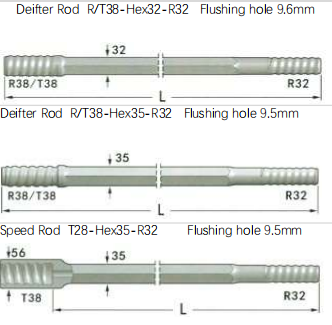

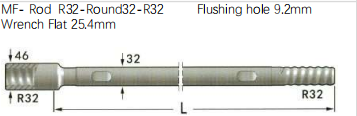

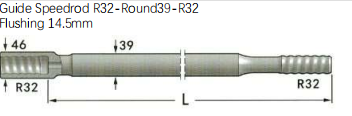

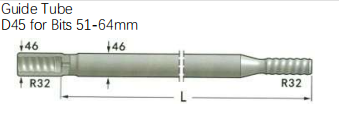

Isku-xidhka isdhaafka iyadoo la adeegsanayo nidaamka dunta R32

• R32 nidaamka dunta

• Si weyn loogu isticmaalo daadinta iyo tunnelka

Midabka:Madowama Iyada oo ku saleysan shuruudaha macaamiisha

Waxyaabaha: Tungsten carbide iyo birta aluminiumka ah ee xoogga sare leh

Habaynta: Shididada CNC iyo habka daawaynta kulaylka iska leh

Nooca: R32 Isku-xidhka Isku-dhafka

Codsiyada

• Macdanta dhulka hoostiisa mara

• Tunnelka

Faa'iidada tartanka

Birta chromium-molybdenum oo xoog badan leh oo leh daal badan iyo iska caabin aad u fiican

Sawir

| Tirada Dalbashada Ugu Yar | N/A |

| Qiimo | |

| Faahfaahinta Baakadaha | Xidhmada Dhoofinta caadiga ah |

| Waqtiga dirida | 7 maalmood |

| Shuruudaha Lacag-bixinta | T/T |

| Awood-siinta | Iyada oo ku saleysan Amarka Faahfaahin |

-

T38 190mm Dubbada Sare ee Tuubbada Isku-dhafka ah

-

Xadhkaha iska caabinta Dharka Sare ee T38 T45 T51 Couplin...

-

Dhererka Gacan-gacmeedka Isku-xidhka T45 ee Been-abuurka 210mm ...

-

Dube-Dhexeedka Sare ee Isku-xidhka Gacanta T38 T45 T51...

-

ST58 Dharka Isku-xidhka Tooska ah ee Macdanta Dhulka Hoostiisa

-

Isku xirka istaandarka istaandarka isku dhafka ah ee dunta gacmaha R32 ...