| Xaaladda: | Cusub | Nooca Habaynta | Been abuurasho |

| Warshadaha lagu dabaqi karo: | Tamarta & Macdanta, Qodista Dhulka Hoostiisa iyo Qodista Dusha Sare | Isticmaal | Macdanta macdanta, dhagaxa qodista, macdanta, qarxinta, dhisidda, xoogaa furan iwm. |

| Fiidiyowga kormeerka-baxaya | Bixiyay | Tayada | 100% tayada isku midka ah ee noocyada ugu sarreeya adduunka |

| Warbixinta Tijaabada Mashiinada | Bixiyay | Faa'iidooyinka | tayada sare iyo qiimaha warshadda |

| Nooca Suuqgeynta | Alaabta caadiga ah | Nooca Boby | Nooca caadiga ah ama nooca gadaal |

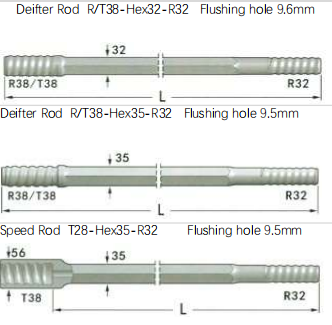

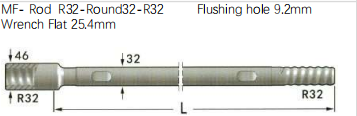

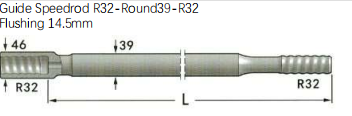

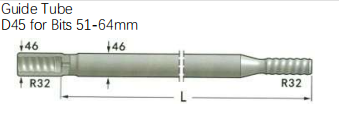

| Magaca Summada | JCDRILL | Dulqaad | R25, R28, R32, R3212 R35, R38, T38, T45, T51, ST58, GT60, GT68 |

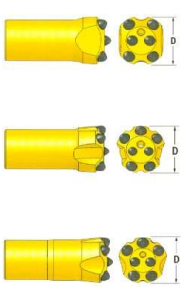

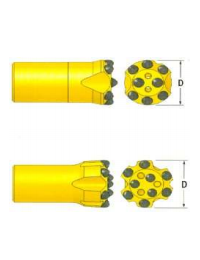

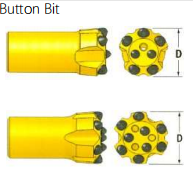

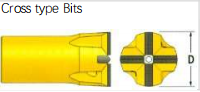

| Nooca | Button Thread Bit | Tungsten carbide | wareegsan, ballistic, Conical, Hemispherical |

| Nooca Mashiinka | Qalabka qodista | Nooca xaqiiqda | Xarunta la dhigo, Waji fidsan, Convex, Concave, iwm |

| Qalab | Birta kaarboon |

Hordhac

Xirmooyinka badhannada dunta ee JCDRILL waxay bixiyaan xoogga hogaaminta iyo heerarka dhexgalka ee warshadaha si ay u helaan wax soo saar badan, toosan aad u fiican iyo dalool tayo nadiif ah, oo leh waxqabadka ugu sarreeya ee qodista dhagaxyada dhagaxyada leh nolol dheer si loo badbaadiyo heerka qiimaha shidaalka.R32-76mm qaniinyada dunta ah ayaa si gaar ah loogu talagalay samaynta dhagax adag.

Waxaan dooran doonaa inaan isticmaalno tungsten carbide of T6, oo ay kujirto iska caabin wanaagsan iyo adayg.

Noocan carbide ah ayaa horeba loo caddeeyey inuu yahay kan ugu fiican adduunka oo uu kula tartamayo magacyada waaweyn ee adduunka muddo dheer.

Dhanka kale, waxaan dooran doonaa inaan isticmaalno birta sare ee ku habboon tignoolajiyada galinta kulul, taas oo jirka qodista uu u hayn doono badhamada carbide si adag taas oo yaraynaysa halista badhamada'godadka ka soo dhacaya.

Si aad si fiican uga hortagto xajinta dhagaxa, qaabka spherical wuxuu noqon doonaa doorasho wanaagsan oo loogu talagalay carbide haddii xawaaraha sare uusan daruuri ahayn.

Sawir

| Tirada Dalbashada Ugu Yar | N/A |

| Qiimo | |

| Faahfaahinta Baakadaha | Xidhmada Dhoofinta caadiga ah |

| Waqtiga dirida | 7 maalmood |

| Shuruudaha Lacag-bixinta | T/T |

| Awood-siinta | Iyada oo ku saleysan Amarka Faahfaahin |

-

Qodista Dubbada ugu Saraysa R3212 Button Thread Drill B...

-

R32 T38 Button Qulqulka Toosan Dhexroorka 35mm...

-

Mashiinka dunta dubbe ee ugu iibinta fiican...

-

R28 Dhexroorka 43mm 7 badhannada badhanka xadhigga

-

St58 St68 Dib-u-noqoshada Badhan Taxanta ah...

-

127mm 140mm 152mm ST68 Badhanka Thread Retrac Bit...