| Magaca Summada | JCDRILL | Faa'iidada | Soo saaraha tooska ah |

| Nooca | Tungstern Carbide Threaded Drill Bits | Codsiga | Mine, Macdanta, Tareenka, Tunnel, Waraabka Biyaha iwm. |

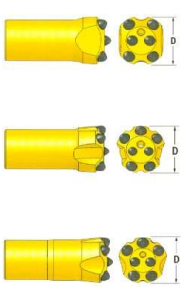

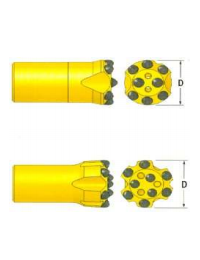

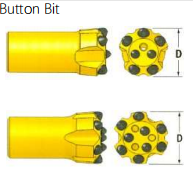

| Nooca Mashiinka | Qalabka qodista | Muuqaal | Heerka Galitaanka Degdega ah ee leh iska caabin xidhid wanaagsan |

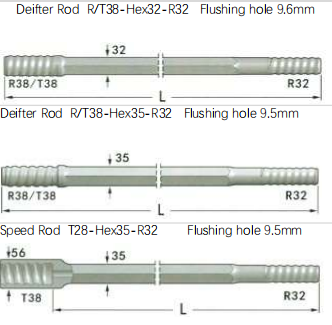

| Qalab | Tungsten Carbide iyo Birta Alloy Tayada Sare leh | Taran | R25 R28 R32 R38 T38 T45 T51 iwm |

| Nooca Habaynta | Qaadista | Summada ku habboon | Atlas copco,Boart longyear,Halco,Fantini,Furukawa... |

| Isticmaal | Qodista Dhagaxa, Macdanta Dhulka Hoostiisa, Quarry, Qarax, iwm | Magaca | Tungstern Carbide Threaded Button Rock Drill Bits |

Hordhac

Sharaxaada

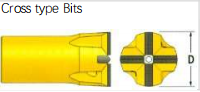

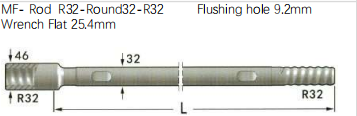

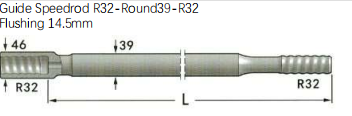

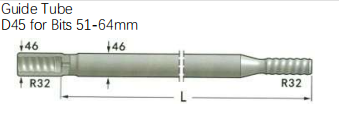

Wershada qodista dhagaxaJcdrill: R32 dun iskutallaabta ah, dhexroor 45-76 mm ku habboon marin-u-qaadista iyo dalbashada qodista tunnelka, si ka fudud in la afeeyo marka loo eego X-bits, xaglaha inset-ku waa siman yihiin dhammaan afarta dhinac, Bits 64mm iyo wax ka yar way fududahay in la afeeyo marka loo eego badhanka badhanka isla cabbirka, xaaladaha dhagaxyada qaarkood, iskutallaabtu waxay u muuqdaan inay soo saaraan dalool shan geesood ah oo wareegsan (gaar ahaan dhexroor ka weyn 64 mm).

Faa'iidooyinka:

Marka la barbardhigo summadaha dibadda, faa'iidooyinkayadu waa hoos:

a.Alaabtayadu waxay la mid noqon karaan in ka badan 95% marka loo eego alaabtii asalka ahayd

b.Qiimaha ayaa la tartamaya noocyada caanka ah iyo tayada ugu fiican ee warshadda yar

Nagu saabsan:

1. Warshadeenu waxay ku takhasustay soo saarista agabka qodista iyo qalabka dayactirka in ka badan 15 sano.

2. Waxaan haysanaa tignoolajiyada iyo qalabka horumarsan.

3. Farsamoyaqaankeenu waxa uu leeyahay khibrad shaqo oo ka badan 15 sano.

4. Qalabka dhagaxa qodida ayaa loo dhoofiyaa aduunka oo dhan.Suuqa ugu weyn: Norway, Turkey, USA, Canada, Australia, Brazil, Uruguay, Philippines, Thailand, India, iwm.

Iskutallaabta Iskutallaabta Iskutallaabta Crown Boring Drill Bit waxaa loo isticmaali karaa xaalad kasta oo qodista dhagaxa, si dhib leh uma saamayso qaabka qalabka qodista iyo waxqabadka dhagaxa.Guud ahaan, qashin-qubka waxaa inta badan loo isticmaalaa dhagax adag, iskutallaabta

Qodista dhagaxa dhagaxa waxa laga sameeyaa daawaha adag iyo bir gaar ah, oo guud ahaan la jaan qaada laydhka dhagaxa fudud, si loo qodo godka dhagaxa dhexroorkiisu yahay 50mm.Qalabka qodista waxaa loo isticmaalaa macdanta birta, sahaminta juqraafiyeed, dhismaha ilaalinta biyaha, korontada, taraafikada, tunnelka, dhagaxa dhagaxa, dhismaha difaaca qaranka iwm.

Sawir

| Tirada Dalbashada Ugu Yar | N/A |

| Qiimo | |

| Faahfaahinta Baakadaha | Xidhmada Dhoofinta caadiga ah |

| Waqtiga dirida | 7 maalmood |

| Shuruudaha Lacag-bixinta | T/T |

| Awood-siinta | Iyada oo ku saleysan Amarka Faahfaahin |

-

R25-45mm Iskutallaabta Xadhkaha Leh ee Qodista Dhagaxa

-

R25 Thread Cross Type Bit oo leh Tungsten Carbide...

-

R32 - 43mm Qulqulka Qulqulka Qulqulka Dhagaxa Dhagaxa

-

Dhererka caadiga ah 51MM Iskutallaabta Iskutallaabta ee Toosan...

-

Qalabka Daloolka Yaryar R25-51mm

-

T60 kursiga qodista dhagaxa qodista cross nooca dri ...